- Home

- Products

- Assembly components

- Accessories for linear units

- Accessories for linear units

Simple.Flexible.Connection

Guide elements for single tube linear units:

Nearly all clamping connectors with through-holes can also be used as guide elements for linear units. They then carry the addition -VO (guide element without sliding bush) or -VG (guide element with sliding bushing). A sliding bushing is recommended in applications with very frequent, e.g. motorized adjustment.

Since the beginning of 2017, guide elements of the cross design for single tube linear units on square tube base have been fitted with dowel sleeves to almost completely eliminate longitudinal play within the individual parts. In addition, all square guide elements are adapted to the square tube in a play-optimized manner, which makes them particularly suitable for applications with torsion-loaded guide elements.

Hand wheel HRL:

For manual position adjustment of the guide elements we recommend a hand wheels. They are secured against rotation on the shaft of the linear unit. For different actuation forces, different diameters are available for the respective linear units, e.g.

HRL 5006 KU: Plastic hand wheel with ø 50 mm for shaft ø 6 mm for linear units ø18 mm

HRL10008AL: Aluminum disc hand wheel with ø 100 mm for shaft ø 8 mm for linear units ø30 mm

HRL14012AL: Aluminum spoked hand wheel with ø 140 mm for shaft ø 12 mm for linear units ø40 and 50 mm

Mechanical position indicators PA:

These are available in various mounting positions for horizontal or vertical reading of the guide element position, as well as right- or left-hand increasing, in the colors gray and orange.

Also available are electronic position indicators PA-D with LCD display and programmable display options for electronic position detection!

Adapter AW:

To add a position indicator to an existing linear unit with standard shaft length, you can extend the existing shaft with the adaptor and use the appropriate position indicator.

Clamping plate KP:

To fix the guide element in a set position, either the uide element can be fixed by means of clamping lever on the tube or the spindle can be blocked on the hand wheel by a clamping plate with clamping lever. The guide element now holds its position and cannot be moved.

Inlaying scale:

For accurate reading of the position directly on the guide element, an inserted, glued scale is a favorable alternative. Here you can choose whether the values should increase from left to right, from right to left or from the middle.

Electric drive ARV:

AC geared motor 230V / 50 Hz, with 100U / min and 2.2 Nm, with tip switch forward / back, incl. coupling and motor bracket, ready to plug in. Optionally, mechanical or electrical, digital position displays are available, as well as limit switch integration and swivel mounting.

Alternatively, Fieldbus actuators with Easy Touch Control as a complete system for format adjustment to control several linear units are available on request.

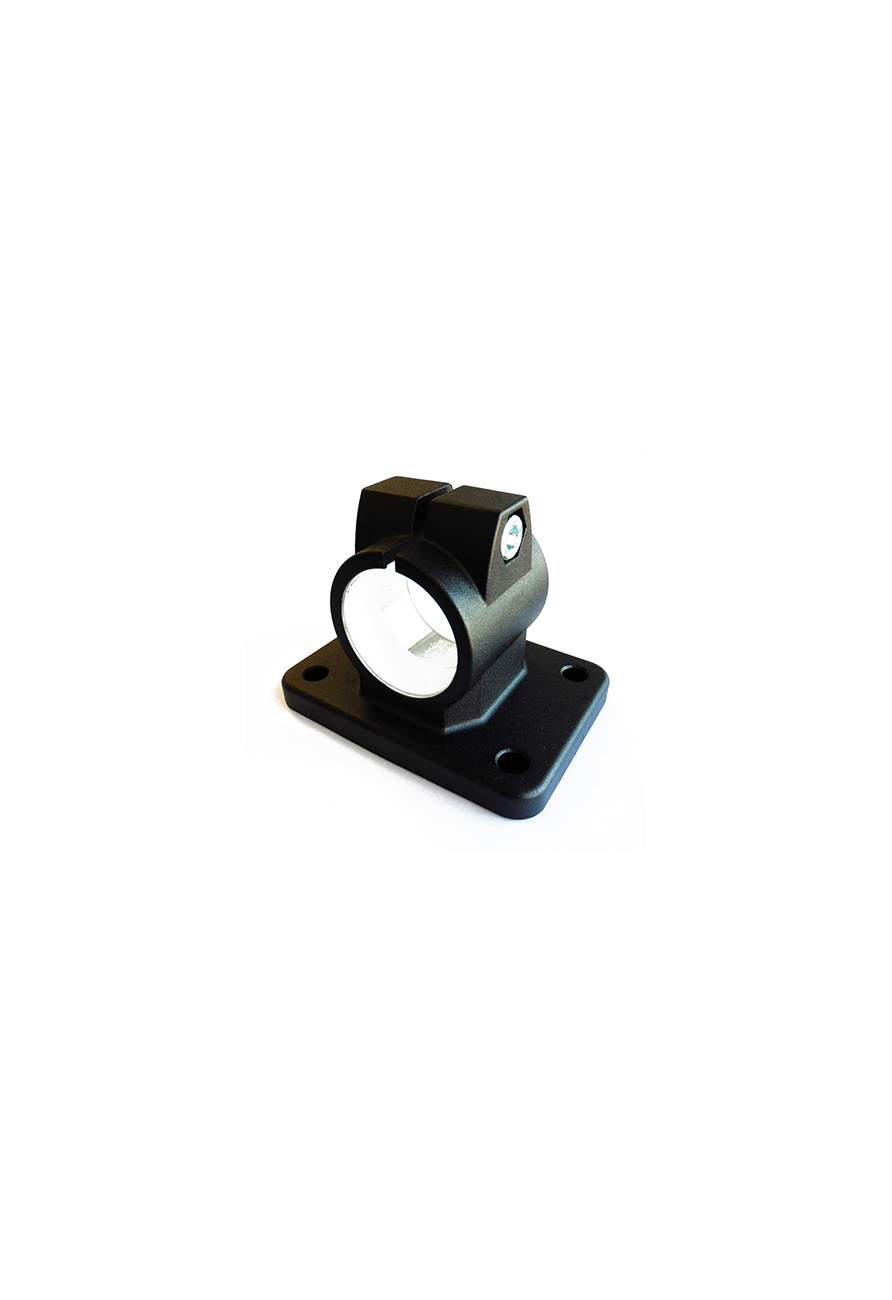

Angle gear WKTR:

For connecting several linear units at an angle of 90° / 180°, we offer different angle gear housings, each as 90° L version or 90° / 180° T version:

- WKTR A-L-L / WKT-A-T-L: compact and shapely aluminum housing anodized or black powder-coated

- WKTR-L-K / WKTR-T-K: similar to our angle clamp connectors WIK, WIS, WIZ

Advantage of this design is the mechanically frictional connection, for which additional supports of the connected components can be omitted

Drive and transmission elements:

- In connection with angle gears, drive or transmission elements are required, e.g. for connecting two or more parallel arranged linear units

- as well as tube extensions and parallel linear unit systems.