- Home

- Products

- Assembly components

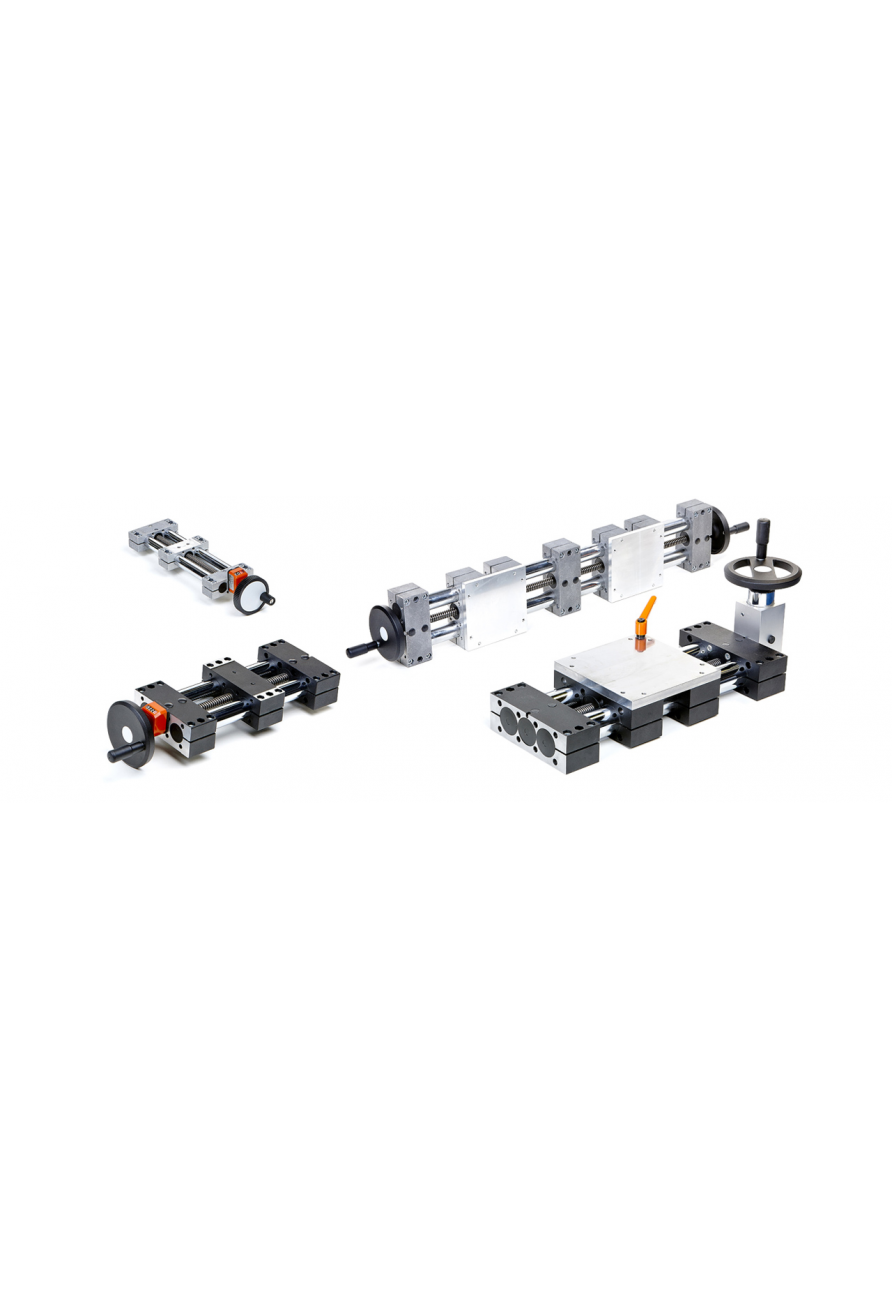

- Double tube linear units

- Double tube linear units

Simple.Position.Adjustment

Simple tube-based spindle axis for manual or electrical position adjustment of your application, e.g. for format, height adjustment or width adjustment on production lines.

Our range includes steel and stainless steel variants in tube diameters ø 18, 30, 40, 50 and 60 mm for a wide variety of tasks.

With these adjusting spindles with hand wheel, a trapezoidal threaded spindle with a guide nut is ball-bearing mounted between two guide tubes, and between two end elements a guide element moves on the double-tube system over the stroke range.

This sturdy design is characterized by its high load capacity combined with maximum torsional rigidity and accuracy and is available in the variants with single guide element or double guide element with connecting plate in the three versions:

2 = left-hand thread, 1 shaft

3 = right-hand thread, 2 shafts

4 = left-hand thread, 2 shafts

5 = right and left hand thread, 1 shaft

6 = right and left hand thread, 2 shafts

7 = 1x right and 1x left-hand thread (split), 2 shafts

8 = 2x right-hand thread (split), 2 shafts

9 = 2x left-hand thread (split), 2 shafts